Machine Information

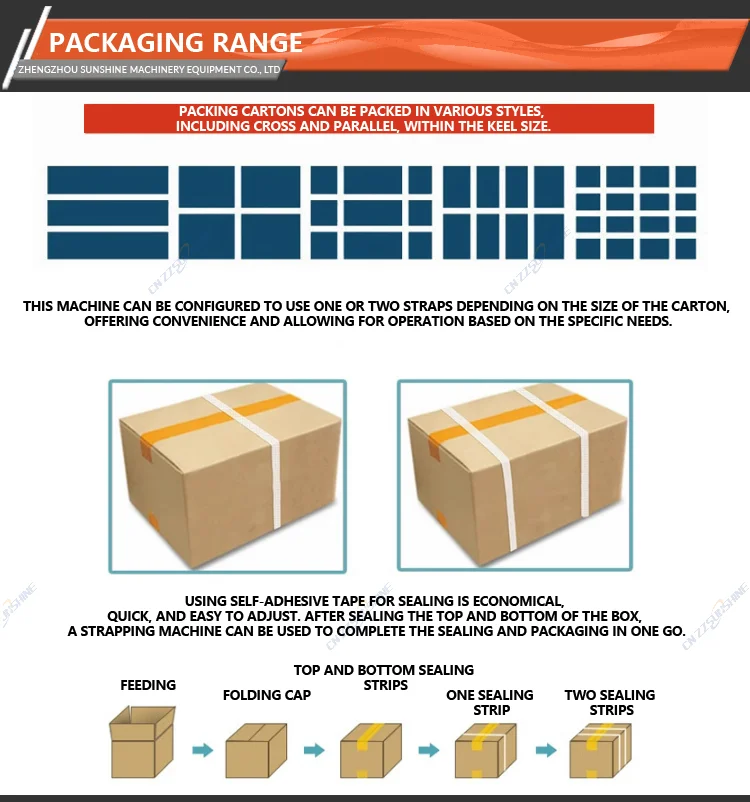

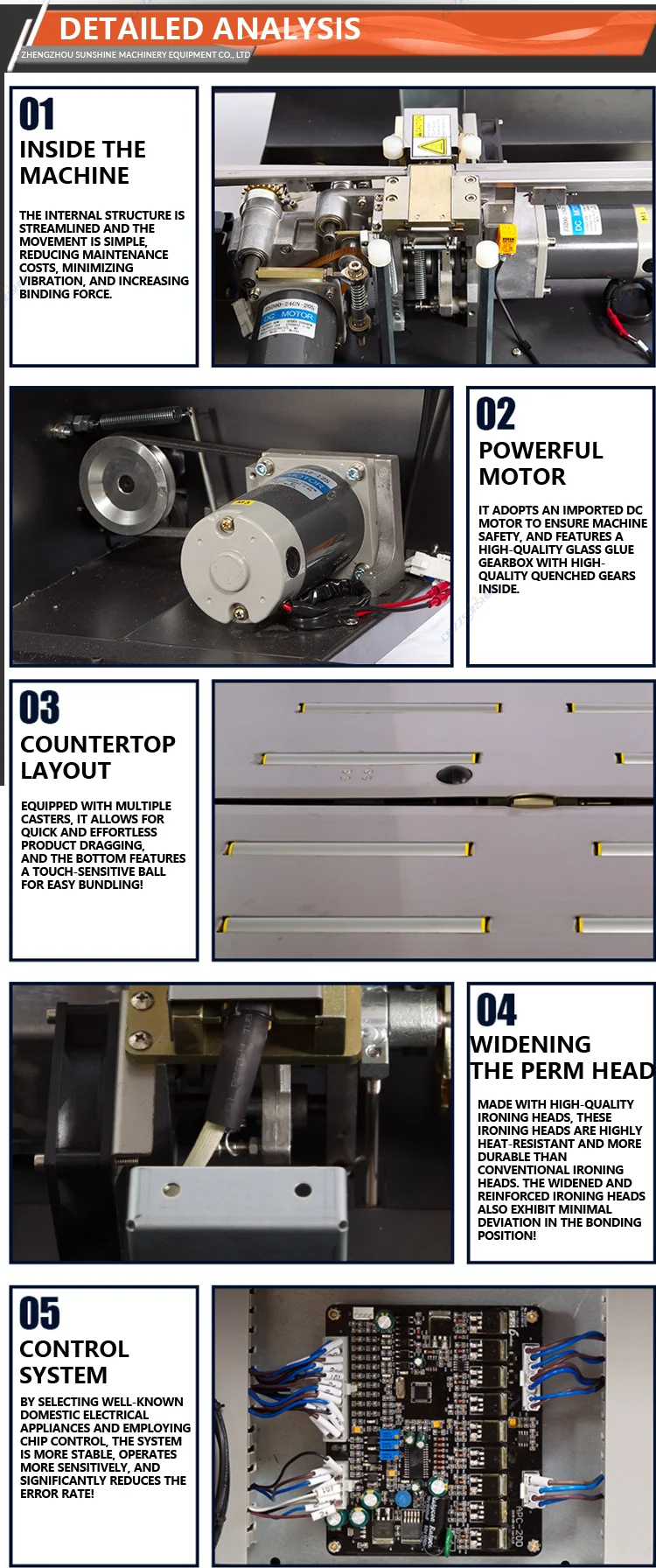

The fully automatic strapping machine is designed for the final packaging process, which involves tying cardboard boxes with strapping to prevent them from scattering during transportation. There are many advantages to using an automatic strapping machine, such as the beautiful and sturdy strapping produced from cardboard boxes, fast speed, and improved packaging efficiency for workers. At the same time, reducing waste also saves costs. Divided into plastic strapping machines, steel strapping machines, fusion strapping machines, etc.

The packaged object is basically in the middle of the strapping machine. First, the right top body rises and presses the front end of the strap, tightening the strap onto the object. Then, the left top body rises and presses the appropriate position of the lower strap. The heating element extends into the middle of the two straps, and the middle top knife rises to cut the strap. Finally, the next strapping strap is delivered to its position, completing a work cycle.

The control system of the fully automatic strapping machine consists of a core control unit PLC and a human-machine interface for operation. The core control unit is controlled by LG "PLC", and the hydraulic system is the core part of the pressurized strapping machine. Its reliability directly determines whether the strapping machine operates normally and reliably. Among them, oil temperature control becomes the key to the hydraulic control part of the metal hydraulic strapping machine. For electromechanical equipment, automation, intelligence, and modularization make the design thoughtful, and important parts need to be considered. The service life of each product is determined by a core component, and that core component is often the most valuable one. For example, the core component of a packaging machine is the movement; The core component of the sealing machine is the motor; The core component of the shrinking machine is the furnace; The production of winding machines has been modularized, with core components located in various modules. The core component of a vacuum packaging machine is the vacuum pump. Most small vacuum packaging machines use rotary vane vacuum pumps. This is enough to demonstrate the high technical requirements of packaging machinery production.

Company Introduction

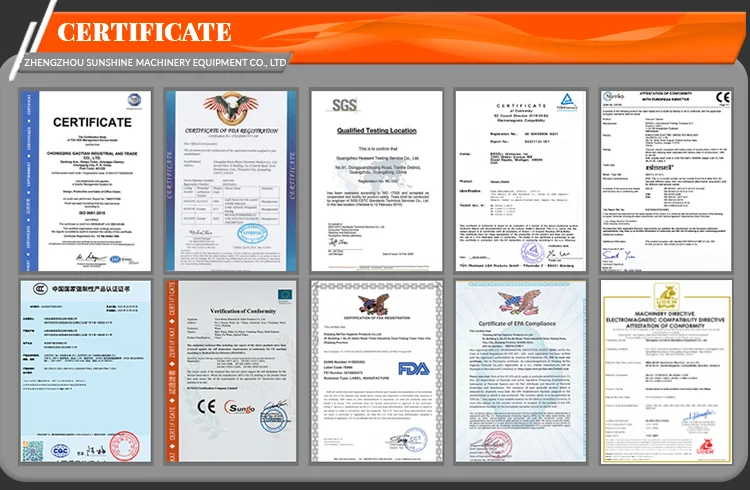

Certification

Client Feedback