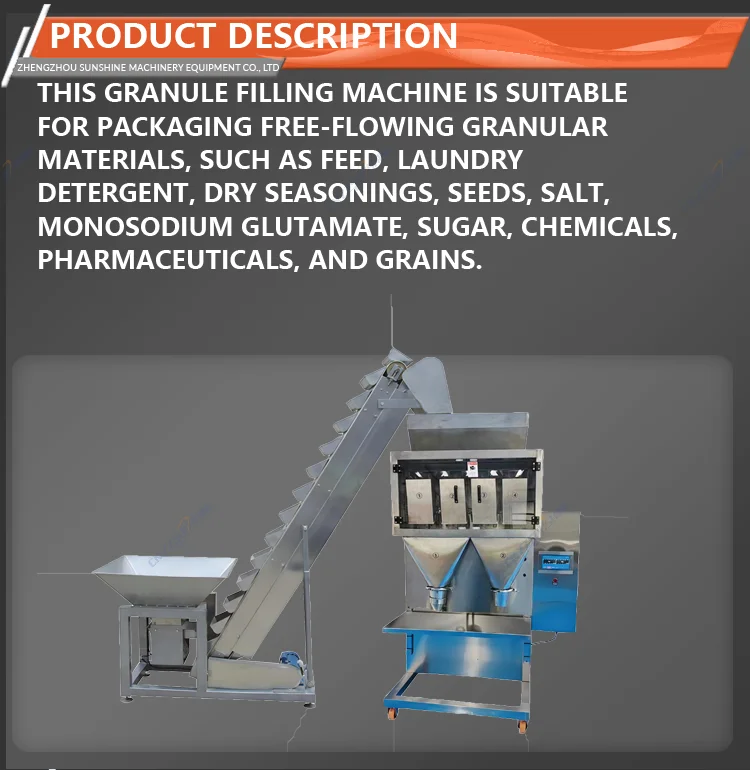

Machine Introduction

Four bucket weighing automatic quantitative packaging machine, controlled by microcomputer. Suitable for quantitative packaging of granular and granular materials such as pesticides, fertilizers, veterinary drugs, premixes, additives, laundry detergent, salt, monosodium glutamate, chicken essence, white sugar, seeds, rice, snacks, and hardware.

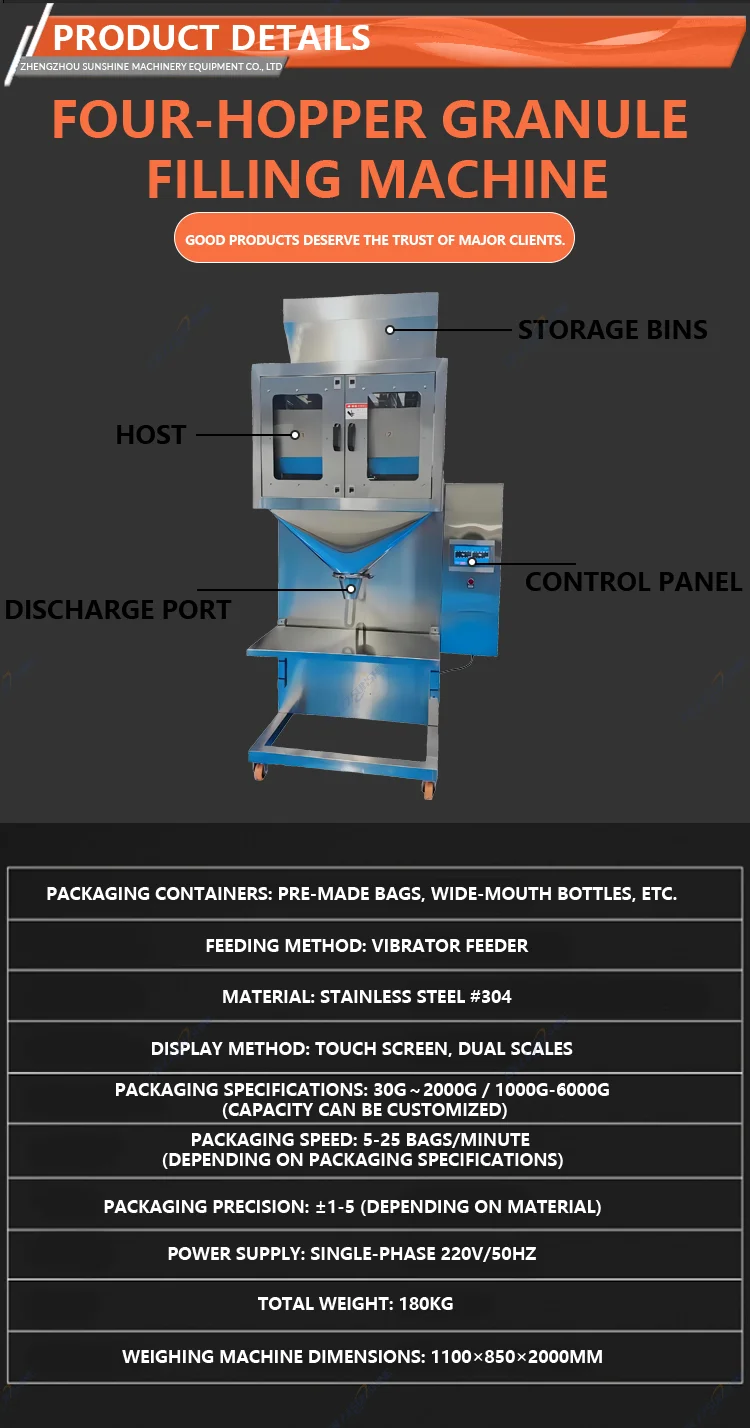

Product Features:

1. Four scale alternating work, fast packaging speed.

2. Strong compatibility and easy to use with other packaging equipment.

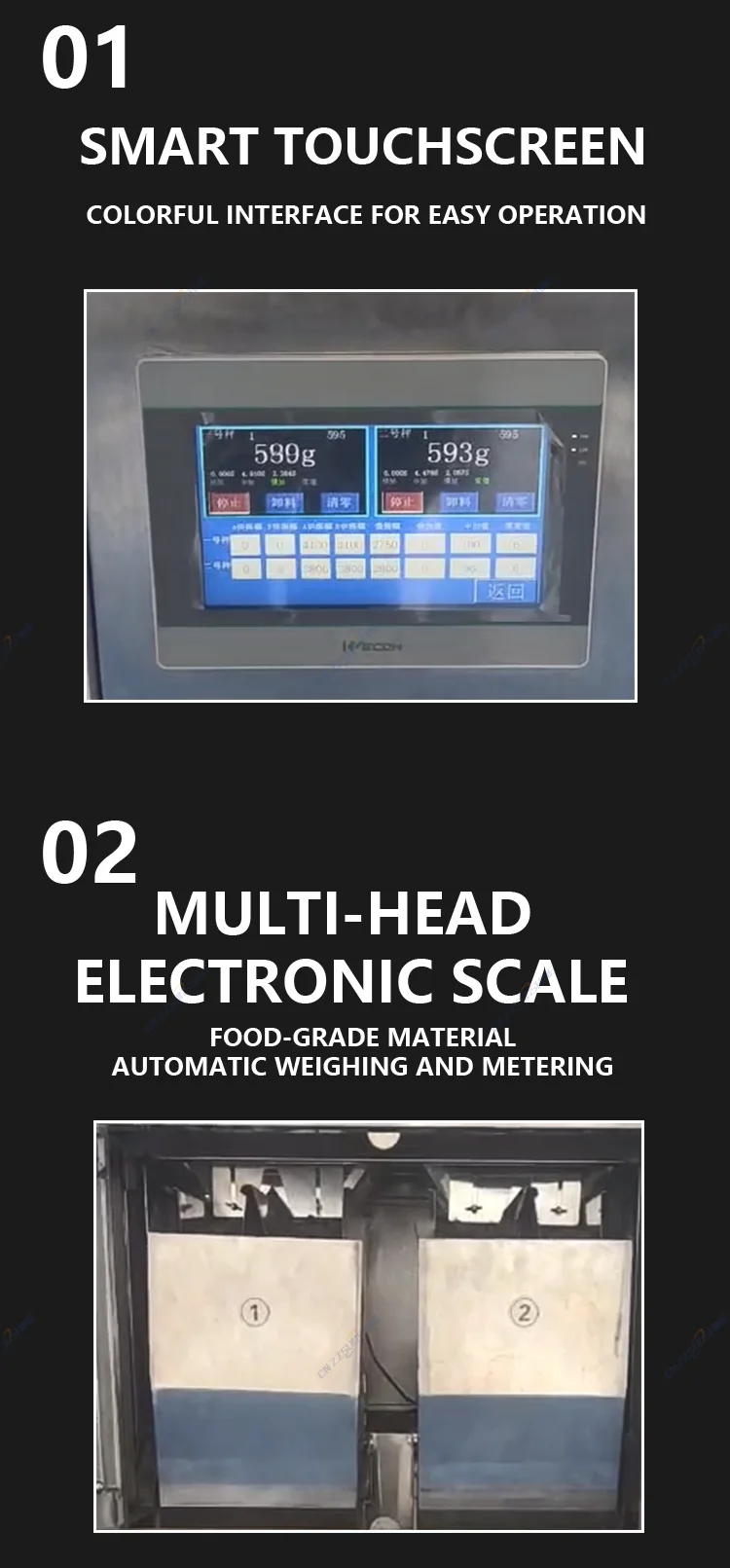

3. High precision digital sensors enable instantaneous precise measurement.

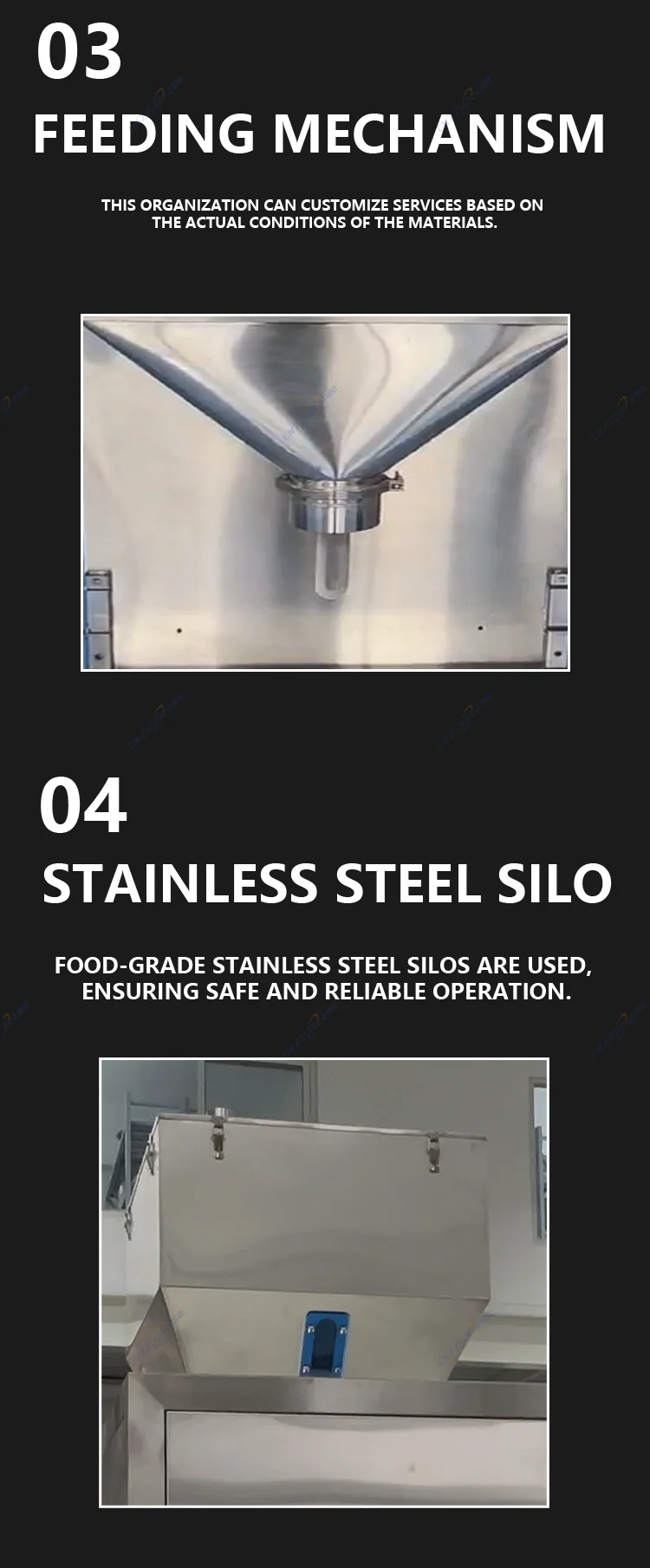

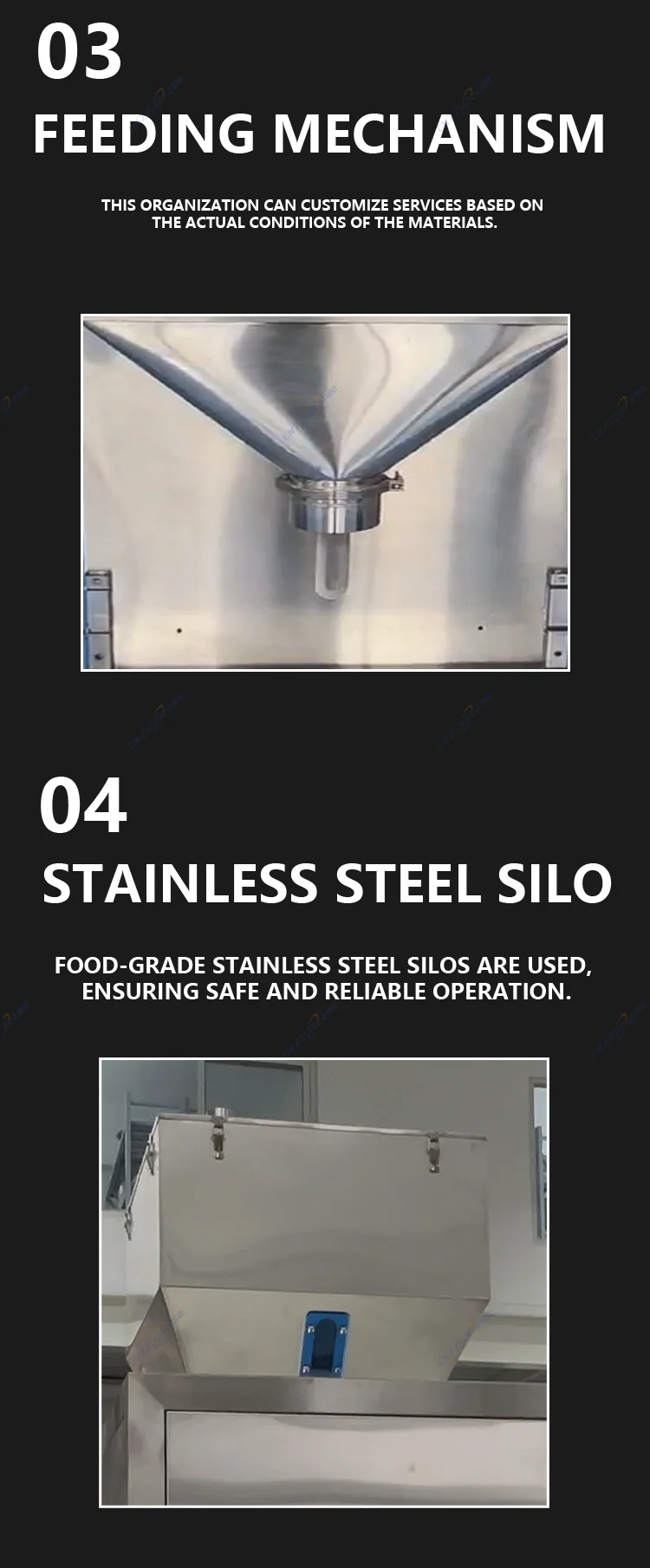

4. Three level vibration feeding achieves high-precision packaging.

5. The parts in contact with the material are made of high-quality stainless steel, which is corrosion-resistant, dustproof, and easy to clean.

6. The weighing bucket can be directly disassembled, making cleaning very convenient.

7. Microcomputer control system, technology, easy operation, and more reliable use.

The four bucket scale granule packaging machine is one of the common automated packaging solutions in industries such as food, chemical, and pharmaceutical. It achieves a precise feeding mode of "fast addition+slow addition" through the collaborative work of four independent weighing buckets, significantly improving packaging speed and weight accuracy. This type of equipment is widely used in the production lines of various granular products such as tea, nuts, miscellaneous grains, and feed, meeting the packaging needs of large quantities and high efficiency.

Flexible packaging: It can achieve the proportional mixing and bagging of single or multiple materials, adapting to complex formula requirements. Easy to operate: adopting a modular control system and touch screen interface, with simple parameter settings and low maintenance costs. High sealing quality: equipped with intelligent temperature control system and embedded heat sealing mechanism, the sealing pattern is clear and the sealing performance is strong. High degree of automation: capable of automatically completing the entire process of measuring, bag making, filling, sealing, cutting, counting, etc.

Company Information

Zhengzhou Sunshine Machinery Equipment Co., Ltd. is a cross-border e- business enterprise which focuses on small and medium-sized machinery and equipment series products and peripheral products.

Our company is mainly engaged in small and medium-sized soap production equipment, oil refining equipment, soap grain oil processing production line, mixing equipment and packaging equipment and other chemical products.

The products are exported to all over the world, won the praise of many cooperative customers, has become an important member of international trade enterprises in Henan Province.

The company always adheres to the enterprise spirit of ‘integrity’, ‘self-discipline’ and ‘gratitude’. With a strong cross-border network sales team and perfect supply chain system. Timely supply and thoughtful service.

Certification

Client Feedback

FAQ

Q1: How to find a machine suitable for my product?

Tell us about your product details and packing requirements.

1. What kind of product you would like to use?

2. How much capacity per hour do you need?

3. You requirement for the machines.

Q2: Is engineer available to serve oversea?

Yes, but the travel fee is responsible by you. In order to save your cost, we will send you a video of full details machine installation and assist you till the end.

Q3. How can we make sure about the machine quality after placing the order?

Before delivery, we will send you the pictures and videos for you to check the machine quality. And also you can arrange for quality checking by yourself or by your contacts in China.

Q4. We are afraid you won't send us the machine after we send you the money?

We have our business license and certificate. And it is available for us to use trade assurance service,guarantee your money, and guarantee your machine's on-time delivery and machine quality.

Q5. Can you explain me the whole transaction process ?

1.Sign the Contact

2.Arrange 50% deposit to our factory

3.Factory arrange production

4.Testing & detecting the machine before shipping

5.Inspected by customer or third agency through online or site test.

6.Arrange the balance payment before shipment.

Q6: Will you provides the delivery service?

1.Yes. Please inform us of your final destination, we will check with our shipping agent to quote the shipping cost for your reference before delivery.