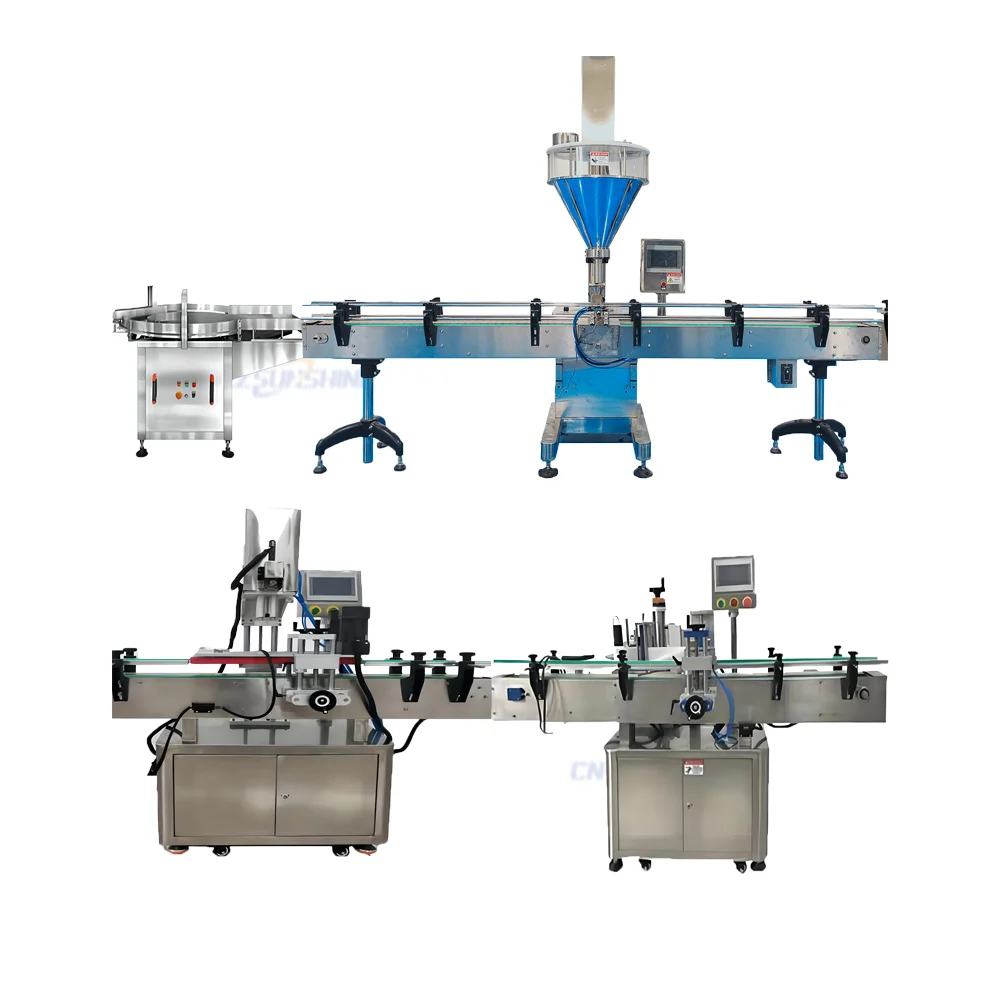

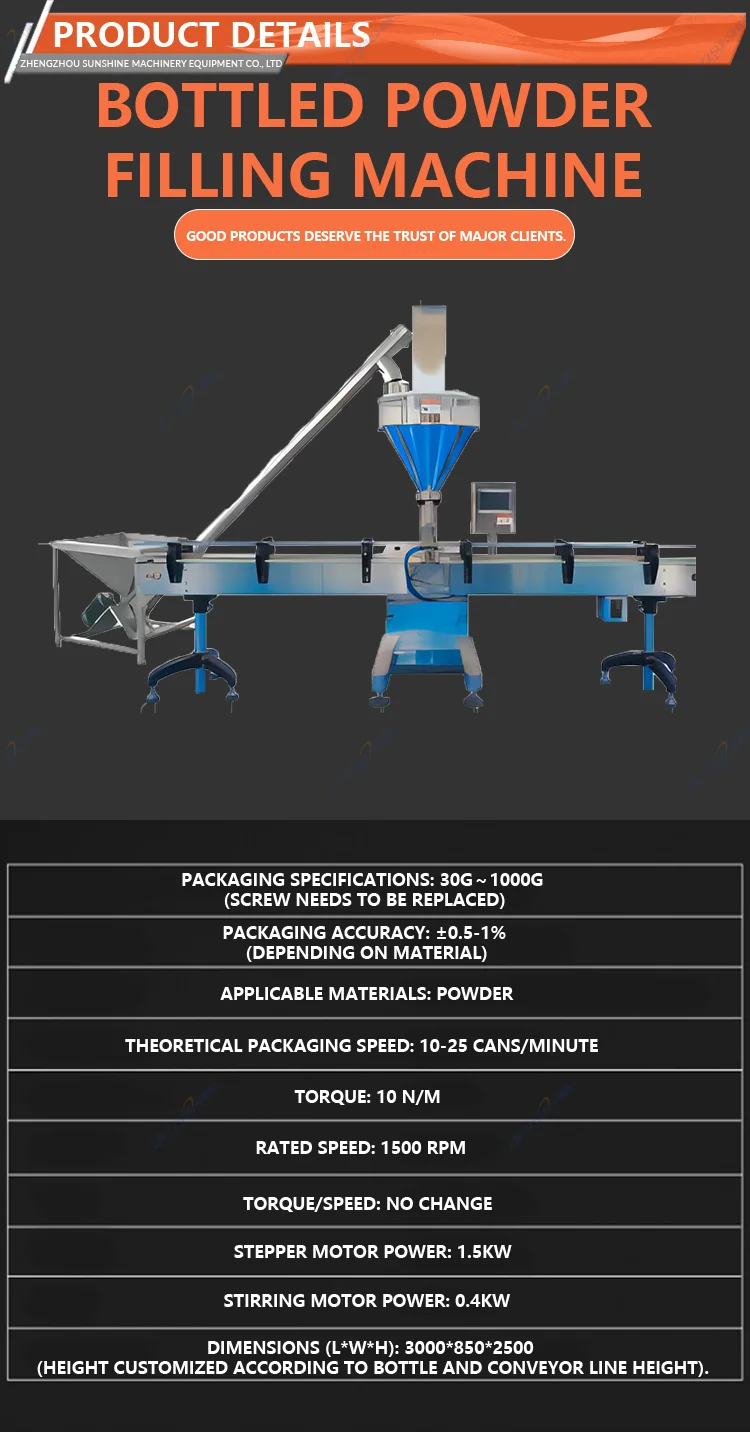

Machine Introduction

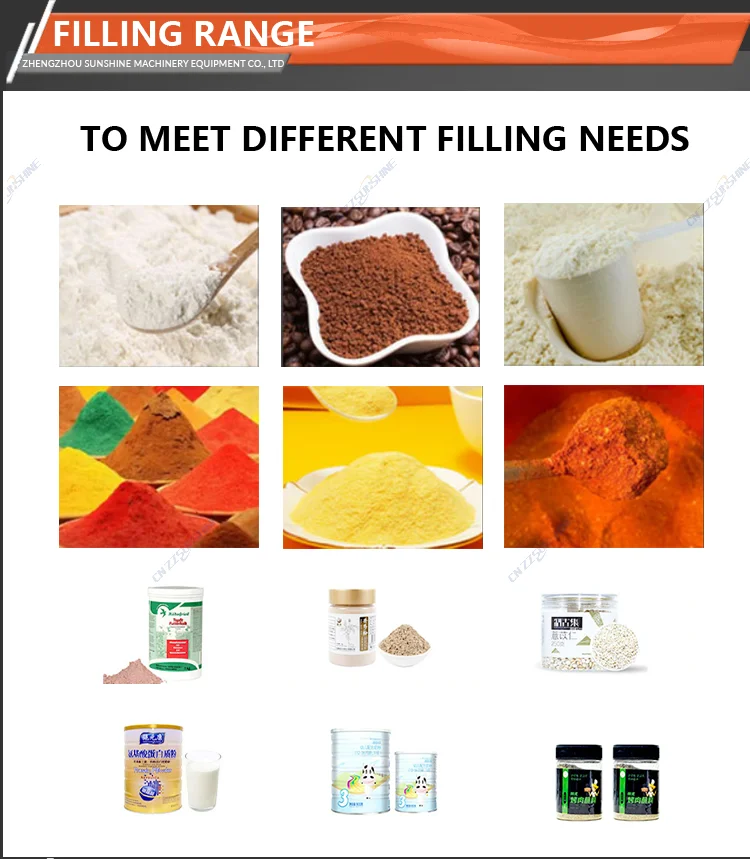

Bottled powder filling machine is a machine used for bottling powder products, which can automatically complete the processes of conveying, positioning, filling, etc. It has the characteristics of high efficiency, precision, and simple operation.

Bottled powder filling machine is a machine that quickly and accurately bottles powder products, and can automatically complete the processes of feeding, quantitative filling, and discharging. It is easy to operate, beginners can quickly get started, the control panel is in Chinese interface, and key parts are easy to disassemble and clean. Filling is fast and accurate, with guaranteed output, suitable for various specifications of penicillin bottles, durable and resistant to manufacturing, reducing downtime troubles. Widely used in industries such as pharmaceuticals, health products, and food.

Powder packaging machine is an automatic packaging equipment widely used in various industries such as food, medicine, cosmetics, etc. Its main working principle is to feed powdered substances into packaging bags through a feeding system, and then automatically complete all packaging processes such as weighing, sealing, and cutting after sealing according to preset parameters, ultimately obtaining a certain amount of bagged powder.

Specifically, the working principle of the powder packaging machine includes the following processes:

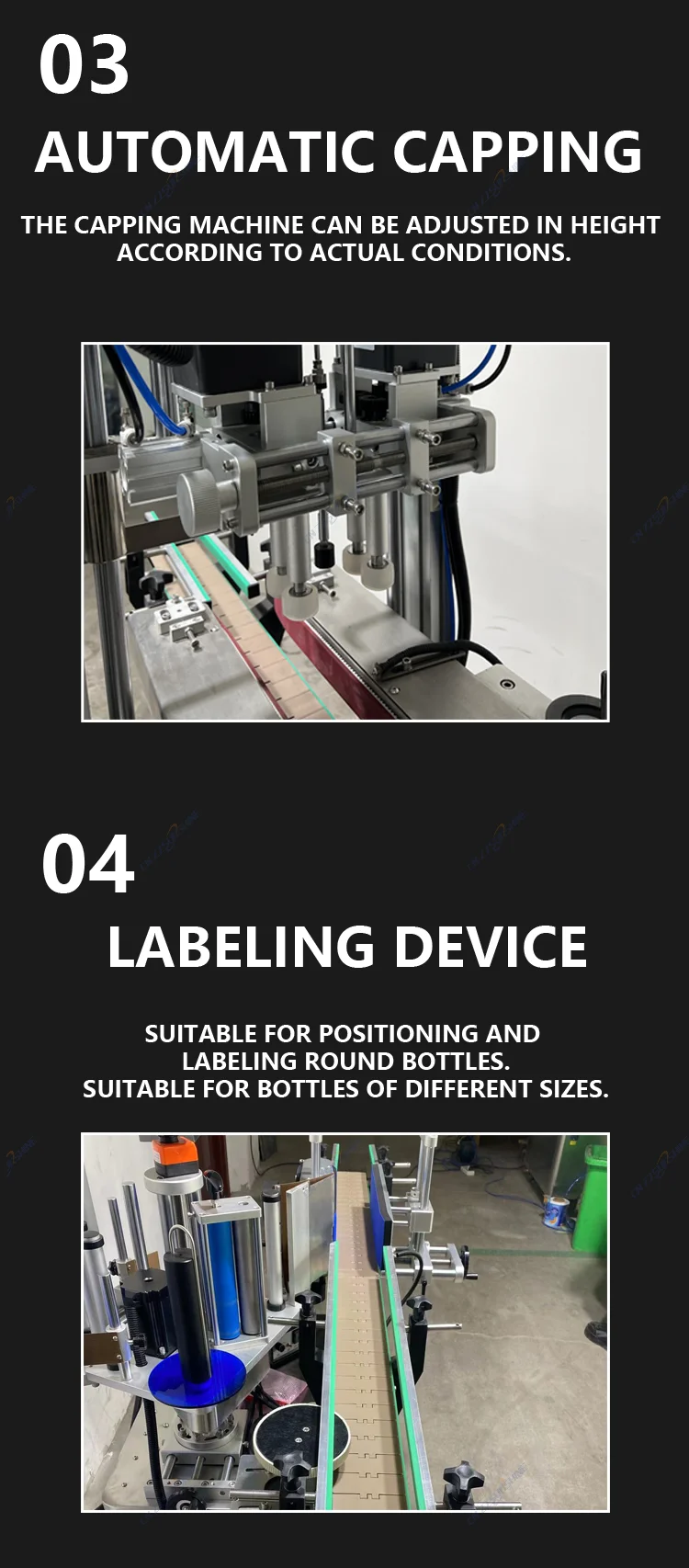

1. Feeding system

The feeding system is one of the most important components in powder packaging machines, which is used to transport powder substances into packaging bags. There are usually two types of feeding systems used, one is a multi head scale, and the other is a screw feeder. Multi head scale is a weighing system that uses multiple weighing devices to control the feeding cut-off signal according to the preset weight of powder substances, achieving weighing operations. The spiral feeder is a powder conveying device, whose main principle is to smoothly transport bagged powder along a specific direction in the material pipeline to the packaging bag by rotating the spiral.

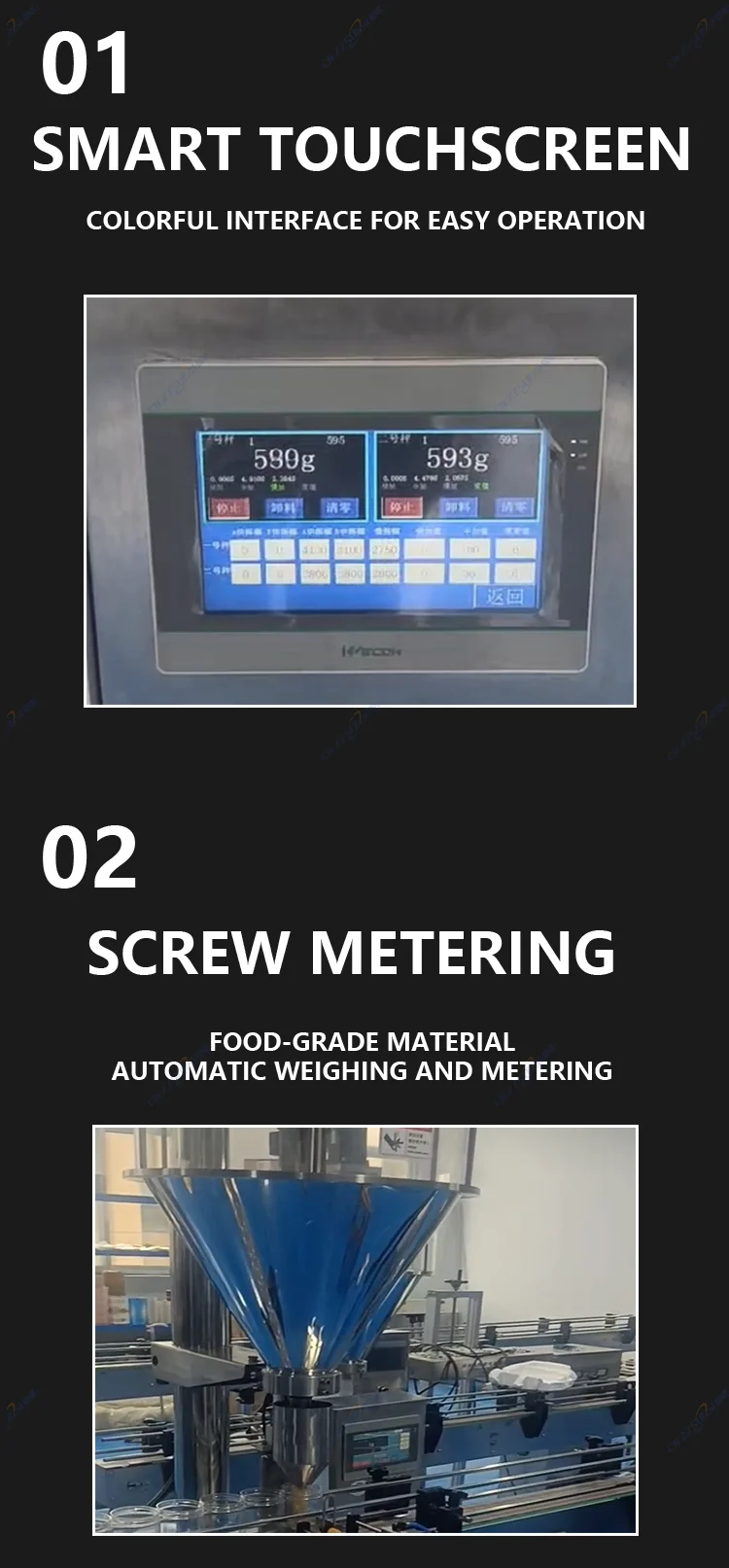

2. Program control system

The program control system is another key component of the powder packaging machine. It can control the entire packaging process, such as adjusting the feeding amount, weighing method, sealing time, speed and other parameters, and can store and call multiple packaging solutions. It uses PLC or computer for program setting and control, which can ensure accuracy and stability during the packaging process.

3. Packaging material system

The packaging materials used in powder packaging machines are mainly plastic film or aluminum foil. The packaging machine rolls these materials into the machine, processes them to form continuous bag shaped packaging materials, and divides them according to the required size to make bag shaped packaging materials.

4. Weighing and sealing system

After the powder material is fed into the packaging bag through the feeding system, the powder packaging machine automatically starts the weighing and sealing mechanism to weigh the bagged powder material in a controlled manner. Then, it is sealed and cut at the serrated edge to form a seal. After packaging is completed, it is output to the outlet, and the entire packaging process is completed.

In short, the powder packaging machine is an efficient, fast, and high-precision automated packaging equipment that has been widely used in industries such as food, medicine, and cosmetics. It has achieved efficient automation of powder material processing through advanced technological means, shortened production cycles, improved production efficiency, and also reduced production costs, providing strong support and assurance for industrial automation and informatization.

Company Information

Zhengzhou Sunshine Machinery Equipment Co., Ltd. is a cross-border e- business enterprise which focuses on small and medium-sized machinery and equipment series products and peripheral products.

Our company is mainly engaged in small and medium-sized soap production equipment, oil refining equipment, soap grain oil processing production line, mixing equipment and packaging equipment and other chemical products.

The products are exported to all over the world, won the praise of many cooperative customers, has become an important member of international trade enterprises in Henan Province.

The company always adheres to the enterprise spirit of ‘integrity’, ‘self-discipline’ and ‘gratitude’. With a strong cross-border network sales team and perfect supply chain system. Timely supply and thoughtful service.

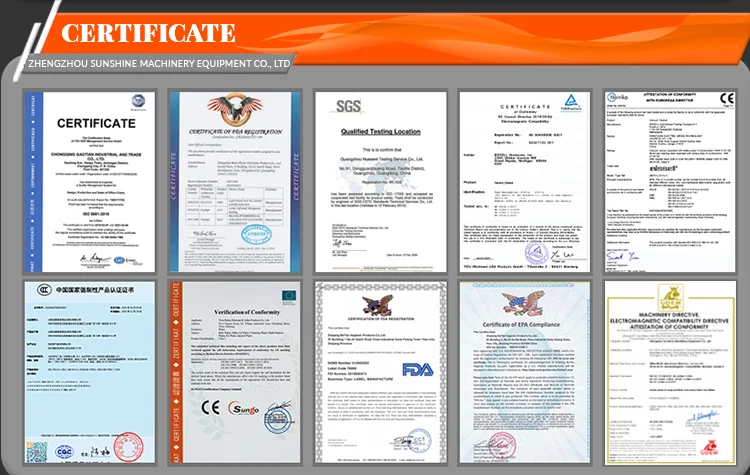

Certification

Client Feedback

FAQ

Q1: How to find a machine suitable for my product?

Tell us about your product details and packing requirements.

1. What kind of product you would like to use?

2. How much capacity per hour do you need?

3. You requirement for the machines.

Q2: Is engineer available to serve oversea?

Yes, but the travel fee is responsible by you. In order to save your cost, we will send you a video of full details machine installation and assist you till the end.

Q3. How can we make sure about the machine quality after placing the order?

Before delivery, we will send you the pictures and videos for you to check the machine quality. And also you can arrange for quality checking by yourself or by your contacts in China.

Q4. We are afraid you won't send us the machine after we send you the money?

We have our business license and certificate. And it is available for us to use trade assurance service,guarantee your money, and guarantee your machine's on-time delivery and machine quality.

Q5. Can you explain me the whole transaction process ?

1.Sign the Contact

2.Arrange 50% deposit to our factory

3.Factory arrange production

4.Testing & detecting the machine before shipping

5.Inspected by customer or third agency through online or site test.

6.Arrange the balance payment before shipment.

Q6: Will you provides the delivery service?

1.Yes. Please inform us of your final destination, we will check with our shipping agent to quote the shipping cost for your reference before delivery.