Visit & Purchase at Our Factory

For customers who want to start soap production, purchasing new equipment is a big deal. Whether the equipment is user-friendly, whether the efficiency is high, whether the quality of the soap produced is stable, and whether the after-sales service is guaranteed Just looking at brochures and videos, these questions always make me feel a bit uneasy.

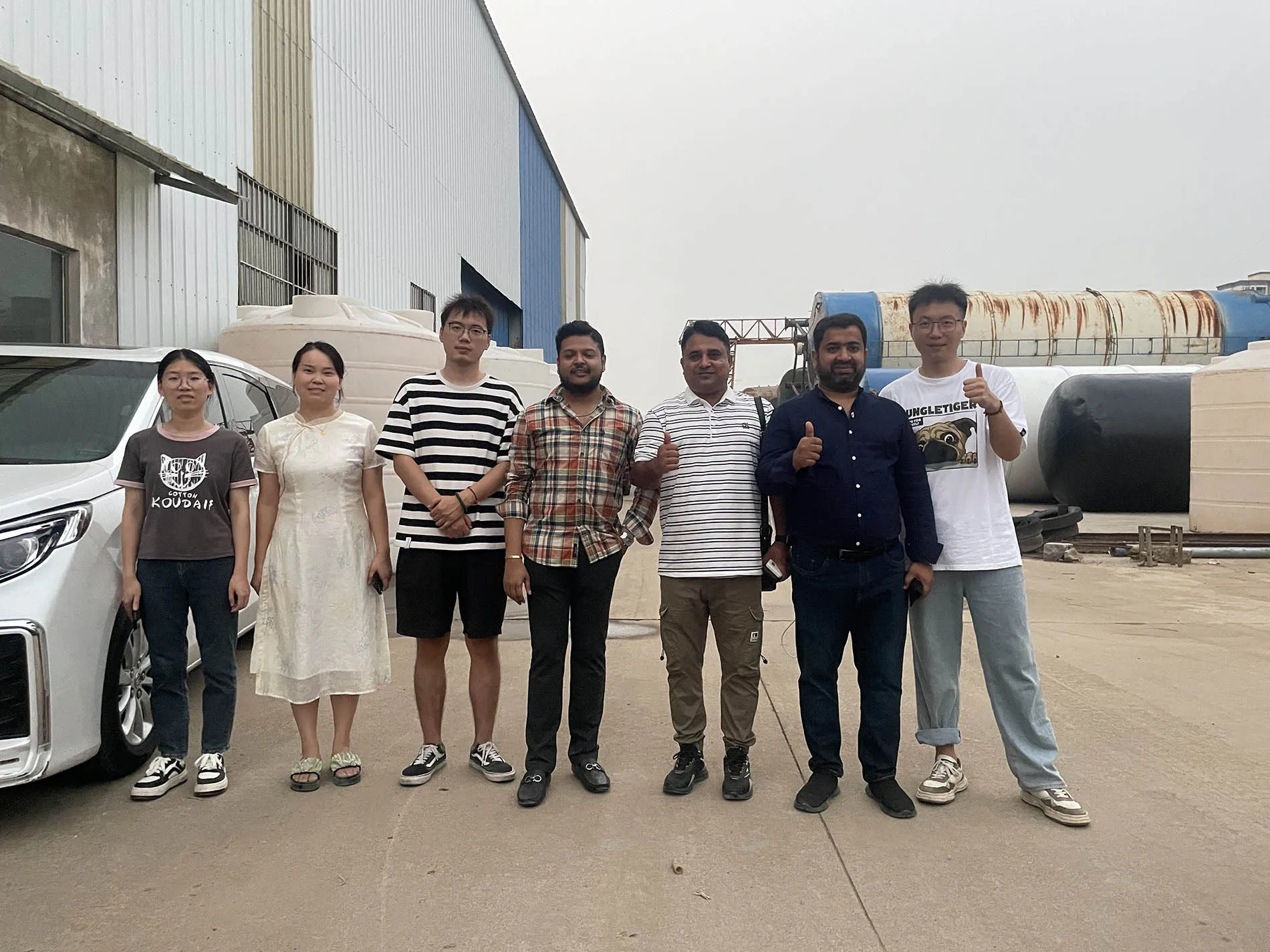

Last week, Mark, a customer from Ivory Coast, came to our factory with their production and technical leaders. They came here this time just to see with their own eyes how our soap production line is made, listen to what our engineers have to say, and most importantly, touch and see with their own eyes how the equipment operates.

Look at the factory: clean and tidy, give it a high score in your heart first

As soon as Mark and his team entered the factory, they praised our clean and tidy production environment. For those who make food and daily chemical equipment, hygiene is the foundation. Your factory is so standardized, and the equipment production environment is definitely not bad, "said Mark. This first impression has given our customers an extra trust in us.

Equipment inspection: Real machine operation, clear effect at a glance

The core part of the visit, of course, is to see the real machine running! We arranged for our clients to focus on several devices that they are concerned about:

Vacuum soap making unit demonstration: Engineer on-site operation, demonstrating how to efficiently mix, homogenize, and strip raw materials such as oil and alkali under vacuum. The customer witnessed with their own eyes the uniform color and delicate texture of the soap base, and was concerned about the core performance of the equipment.

Three roll grinding machine operation: The customer carefully observed the grinding process and inquired about details such as roller material, gap adjustment, and cooling effect. Seeing that the soap body is smoother and more delicate after grinding, I have a direct feeling of improving the quality of soap.

Fully automatic cutting and printing all-in-one machine: This is the equipment that customers are most interested in. Watching the formed soap bars being precisely cut and automatically imprinted with logos, the efficiency is very high. Wang finally settled the bill and said, "This is at least three times faster than our current semi-automatic line, which can save at least three manual workers

Packaging assembly line (optional): If the customer has a need, we have also demonstrated a matching automatic packaging line on how to efficiently complete soap packaging, film wrapping, and boxing.

Talking about craftsmanship: Ask if you don't understand, engineers will answer on site

Just looking is not enough, customers have many specific questions:

What steel is used for the equipment? What is its corrosion resistance? After all, soap is alkaline

Is it convenient to change the mold? We want to make soap in different shapes

How much production can be achieved? How about energy consumption

Is the operation complicated? Are our workers easy to get started with

Is the after-sales response fast? What if there is a problem

Our engineers accompany us throughout the entire process, answering every question face-to-face and hand in hand. Provide material evidence, demonstrate mold replacement on site, explain the operation interface, introduce our services and spare parts inventory Dispel the customer's concerns one by one.

Cost calculation: Clear and transparent, easy to buy

During the visit, we also conducted a preliminary cost-benefit analysis on site based on the actual needs of the customers, such as daily production and product specifications. How much does the equipment cost? How much more can be produced per day? How much labor and utilities can be saved? How long can we recoup our investment? Every account is calculated clearly. Mark has a clear understanding in his heart.

Result: The visit is over and the decision is made on the spot!

After a visit, Manager Mark and his team gained a comprehensive understanding and full confidence in our equipment, technology, and services. Some of the doubts I had during phone calls and online communication have dissipated after seeing and hearing them with my own eyes and ears.

Seeing is believing! "Mark sighed at the end of the visit." The equipment is indeed solid and the operating effect has been seen. Your engineers are also very professional and answered the questions very well. Especially after seeing the trial effect, we have a better understanding. Alright, let's stick to your line

After a pleasant factory visit, Manager Mark signed a purchase contract with us on the spot for a 500kg/h production line!

Sincere invitation: Welcome to "review" our soap machinery!

A total of 1 page 1 data

![[Demo Data]The Top Modern Holiday Gifts for the Design Lover in Your Life2](http://holuo.cn-gd.ufileos.com/hkcms/static/module/index/default/img/new2.jpg)